1, the working principle of the vortex technology: air compression by the orbital motions of the two orbiting scroll. A fixed and the other two vortex rotation. Rotating disk interaction, the air is drawn into the compression chamber, in a continuous compression cycle, dynamic vortex disk through the compression chamber volume to change the pressure of compressed air. The compressed air flow to the center of the vortex, and then is cooled. Because the two vortex dish without any contact with each other at work, the whole compression process without lubrication. As a result, the vortex compressor can make sure we get 100% oil free compressed air.

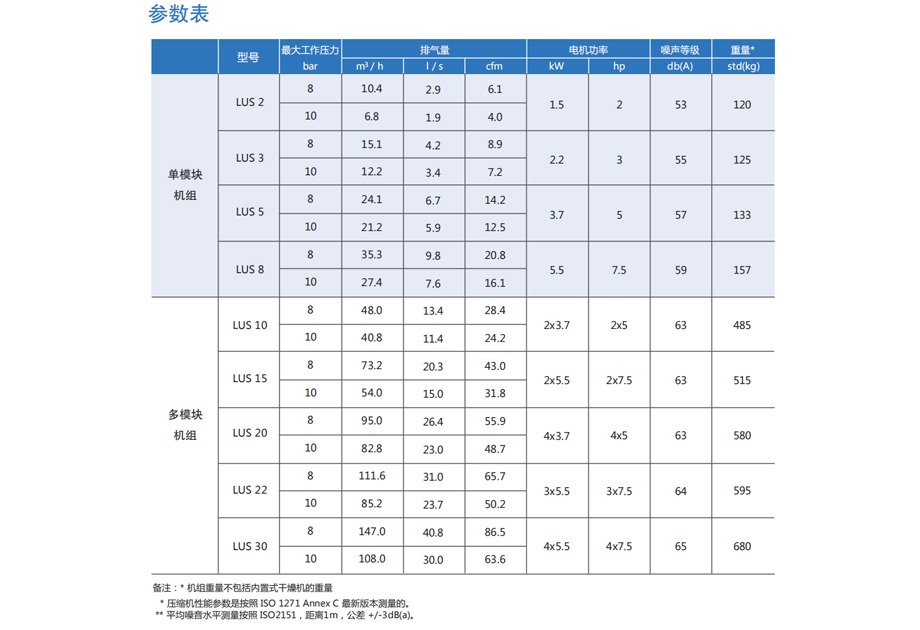

2, key features, and customer value: LUS 2-30 oil-free scroll compressor to provide the high quality of compressed air in the wide industrial fields has important applications, we has been committed to the development of cost-effective energy-saving and environmentally friendly compressor.

3, no oil high quality compressed air: (1) the real 100% oil free and clean air. (2) without filtration system to remove residual oil pipeline no unloading power consumption.

4, energy conservation: 1) no unloading power consumption. (2) with high efficiency level of IE3 motors.

5, stable and reliable, convenient services: (1) high quality material, fewer moving parts to ensure the long time operation and lower service costs. (2) no need for an oil change and waste oil processing. (3) the vertical layout, convenient service.

Scan! To view more

Scan! To view more